Robotiq designs and manufactures flexible robot grippers and complimentary components. Robotiq works with robot manufacturers, integrators and end-users to deliver dexterous grippers that enable new applications and improve productivity.

The 2-Finger Adaptive Robot Gripper has been designed to match Universal Robots in terms of payload, flexibility and user-friendliness.

The 2-Finger Gripper has also been designed to make its installation and programming with Universal Robots easily accessible for everyone. The embedded URCap software also allows the use of several Grippers on the same UR arm.

For maximum versatility and flexibility, the 3-Finger Gripper is the best option. Ideal for advanced manufacturing and advanced robotic research, the 3-Finger Gripper will pick up any object of any shape. The 3-Finger Adaptive Robot Gripper has been designed to match Universal Robots in terms of payload, flexibility and user-friendliness. This robot hand has also been designed to make its installation and programming with Universal Robots easily accessible for everyone.

Hand-E is the first UR+ electric gripper ready for the new e-SERIES generation of Universal Robots..

Robotiq's Camera brings Plug + Play vision for Universal Robots.

Robotiq’s Force Torque Sensors give your Universal Robot the sense of touch. Because it’s a digital signal, the Force Torque Sensor is not affected by surrounding noise and provides a stable, precise measurement of force applied on the process or part.

By installing a Force Torque Sensor on your robot, you’ll be able to reliably perform the following tasks:

Force Copilot is an intuitive software to operate Universal Robots e-Series’ embedded force torque sensor. It accelerates the programming of a whole host of applications, including part insertion and surface finding. Its sensing functions increase flexibility and reliability in machine-tending, assembly, finishing, and pick-and-place applications.

EPick and AirPick are vauum gripper ready for use with the e-Series generation of robots from Universal Robots.

EPick operates without air supply, which makes it highly mobile. The EPick gets easily connected to the cobot wrist and needs no air supply.

The AirPick vacuum gripper is low noise, has a powerful flow and has a compact design for cobots. These vacuum grippers can handle a wide range of applications accordingly, they are ideal for picking up even as well as uneven workpieces made of different materials such as cardboard, glass, dry sheet metal and plastic.

Robotiq’s Sanding Kit makes integrating the hardware and software components for a sanding application with a collaborative robot effortless. It reduces programming time from hours to minutes. Ensure consistent force is applied at each cycle with the software's built-in path generator.

This complete package is ready to go. Open the box, and the hardware and software is already connected. Set-up your application in 3 easy-steps. Experience how seamless it is to use Material Handling Copilot application software.

Optimized, synchronized motion control of the cobot and 7th axis. Plus, seamless movements also mean a longer life cycle for your cobot. The Robotiq Palletizing Solution fits easily within your existing floor plan, given its small footprint. No need to reorganize your floor layout around a central robot.

What's in the Box:

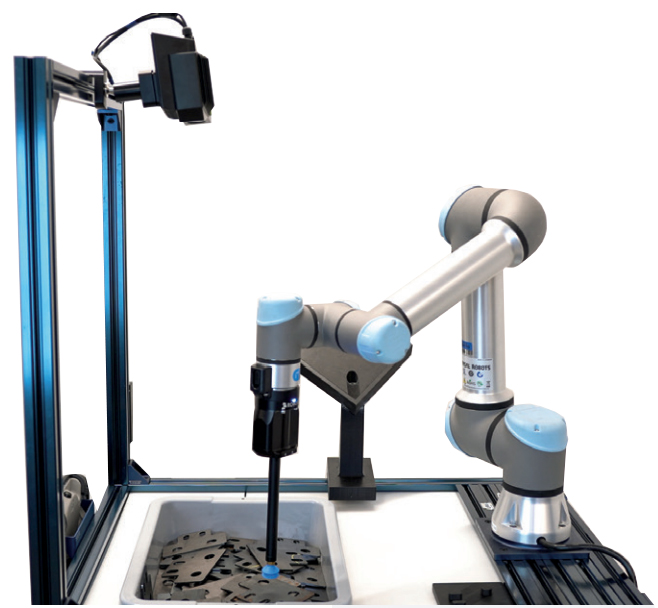

Introduced a bin picking system that provides a complete solution for locating, picking, handling, and placing flat and cylindrical parts. Compatible with cobots from Universal Robots, the Robotiq Bin Picking Kit is designed for appliance manufacturing, automotive components, general industry, and metal and plastic products.

The Robotiq Bin Picking Kit is compatible with bins of up to 800 x 600 x 450mm, handling parts of a minimum size of 10 x 10 x 5mm or flat parts at least 1.5mm thick. The kit is made up of the following components:

Robotiq Screwdriving Solution is designed to fix changeover issues. Within five minutes, the solution can be reconfigured for alternate production. Providing consistent screwdriving around the clock, increasing throughput with a reliable and efficient solution.

Robotiq Screwdriving URCap simplifies programming, because it automates the force- sensing capabilities, as well as the communication between the screwdriver, screw feeder, robot, and vacuum technology.

Screwdriver solution includes:

Clayton Controls is a Robotiq distributor in California, Arizona and Nevada. We offer technical support to help our customers solve their applications.

Copyright © 2022 · All Rights Reserved ·

Clayton Controls Inc. - Headquarters, 2865 Pullman Street, Santa Ana, CA 92705 Tel: 800-235-4411

Campbell Office, 1671 Dell Ave., Suite 110, Campbell, CA 95008 Tel: 800-341-4445

Central California Office, 109 Fox Street, Lemoore, CA 93245 Tel: 800-235-4411

Arizona/Southern Nevada Office, 4343 N. Scottsdale Road, Suite 150, Scottsdale, AZ 85252 Tel: 480-673-3327