SCHUNK offers the world's largest standard portfolio of grippers for all ambient conditions and applications, pneumatically and electrically. The grippers boast robust technology with a long service life, e.g. through the patented multi-tooth guidance. SCHUNK possesses more than 30 years of development and solution competence.

The EGH is the newest member of the the SCHUNK plug&work portfolio specific designed for the use with UR robots. An electric gripper with position control of the fingers. This gripper will be set up and ready to go within 30 minutes from unboxing.

From micro assembly to heavy-load handling, these parallel grippers can handle workpieces with weights of anywhere between a few grams and 80 kilograms, and are suitable for many applications, from the cleanroom to potentially explosive work areas.

The EGI Gripper was specifically designed for challenging and diverse handling tasks in electronics, pharmaceutical and laboratory applications. Individually programmable stroke of up to 57.5 mm per jaw. Flexibly adjustable gripping force of up to 100 N. Components that are sensitive to deformation or fracture can be handled reliably and gently.

Due to the integrated web server, convenient commissioning assistants, active gripping force maintenance, and the certified category C PROFINET interface, the 24 V gripper for small components is one of the most convenient mechatronic grippers on the market.

SCHUNK’s standard centric grippers include small parts, universal, and sealed grippers with three fingers for safe and precise O.D. and I.D. gripping of workpieces, with weight handling capabilities of more than 100 kilograms.

SCHUNK’s large-area electrically actuated grippers are designed for reliable and precise loading and unloading of various ferromagnetic workpieces into and out of machines.

These pneumatic, 4-finger universal grippers are designed for reliable and precise palletizing/depalletizing, and positioning of cylindrical workpieces in assembly and production processes.

SCHUNK’s pneumatic O-ring gripper is predestined for reliable and automatic gripping and assembly of O-rings, square rings, and other rings for shafts and in bore holes. It can work with rings of a diameter between 5 and 160 millimeters for external assembly, and a diameter between 10 and 120 millimeters for internal assembly.

Easily built up 2-finger parallel gripper with good price-performance ratio

Gripping of small to mid-sized workpieces in low-contamination environments with reduced requirements in terms of precision and lifespan and for shorter system run times.

Cost-efficient basic gripper with basic functionalities MPC grippers are

specially suitable for simple applications in small components handling. They offer six unit sizes

for a broad range of applications from small to mid-sized workpieces.

If workpiece sizes vary, angular grippers may be the more economic alternative to parallel grippers, depending on the respective application.

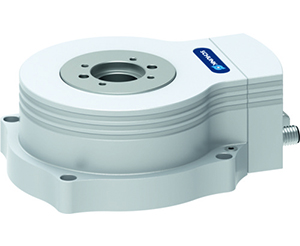

The versatile, and mechatronic SCHUNK ERT rotary unit allows flexible, and dynamically rotational movements in confned spaces, and is almost wear and maintenance-free. Even with the optionally available brake, which is actuated directly via the controller, the height of the SCHUNK ERT remains unchanged. This is a novelty on the market and creates excellent prerequisites for the most compact assembly and handling applicationsin the field of electronics, medical technology, laboratory technology, pharmaceutical, cosmetics and solar industry, but also for space-optimized applications in the field of mechanical engineering, laser machining or for packaging processes.

The MGP-plus combines an oval piston drive with roller guides, guaranteeing a high level of efficiency and making it the 2-finger gripper for small components with the most compact performance on the market. Due to the high force and payload, longer gripper fingers and higher gripping forces are possible with the same gripper size.

The version with protective cover protects the gripper comprehensively against external influences such as splash water, dust, and dirt. The protective cover is approved for use up to IP protection class 54 and certified with cleanroom class 6. The MPG-plus with protective cover is especially suited for workpiece handing in the industries food, pharma and medicine.

Clayton Controls is a SCHUNK distributor in California. We offer technical support to help our customers solve their applications.

Copyright © 2022 · All Rights Reserved ·

Clayton Controls Inc. - Headquarters, 2865 Pullman Street, Santa Ana, CA 92705 Tel: 800-235-4411

Campbell Office, 1671 Dell Ave., Suite 110, Campbell, CA 95008 Tel: 800-341-4445

Central California Office, 109 Fox Street, Lemoore, CA 93245 Tel: 800-235-4411

Arizona/Southern Nevada Office, 4343 N. Scottsdale Road, Suite 150, Scottsdale, AZ 85252 Tel: 480-673-3327