Universal Robots are flexible, lightweight and user-friendly 6-axis industrial robots. They are developed specially for small and medium enterprises, which have the need for flexible and effective automation that can provide them fast return of investments. The robots are easy to move around and do not require sturdy bases due to their lightweight structure. Safety fencing is not needed.

Equipped with intuitive programming, versatile use and an almost endless list of opportunities for add-ons, the e-Series is able to complement production regardless of your industry, company size or product nature.

UR3e: Small but powerful, the UR3e has a payload of 3kgs and reach radius of 500mm. With 360 degree rotation on all wrist joints and infinite rotation on the end joint, this table- top cobot handles high precision tasks and light assembly tasks with ease.

UR5e: The medium-sized member of the Universal Robots family is ideal for automating low-weight processing tasks with its 5kgs payload and 850mm reach radius. Easy to program and fast to set up, the UR5e strikes the perfect balance between size and power.

UR10e: With the ability to automate tasks up to 12kgs with no compromise on precision, the UR10e is the Universal Robots’ family’s most powerful robot. A reach radius of 1300mm also enables it to carry out tasks like packaging and palletizing in facilities where there is a larger distance between different operating areas.

A user friendly and intuitive teach pendant allow operators to program a cobot by moving its arms to the desired waypoints, or simply using drag-and-drop functions on a touchscreen tablet.

UR16e: UR16e delivers an impressive 16kg (35.3 lbs.) of payload an 900mm reach within a small footprint, and is ideal for use in heavy machine tending, material handling, packaging, and screw and nut driving applications. This powerhouse robot allows for heavier end of arm tooling and multi-part handling, and is especially useful for achieving shorter cycle times.

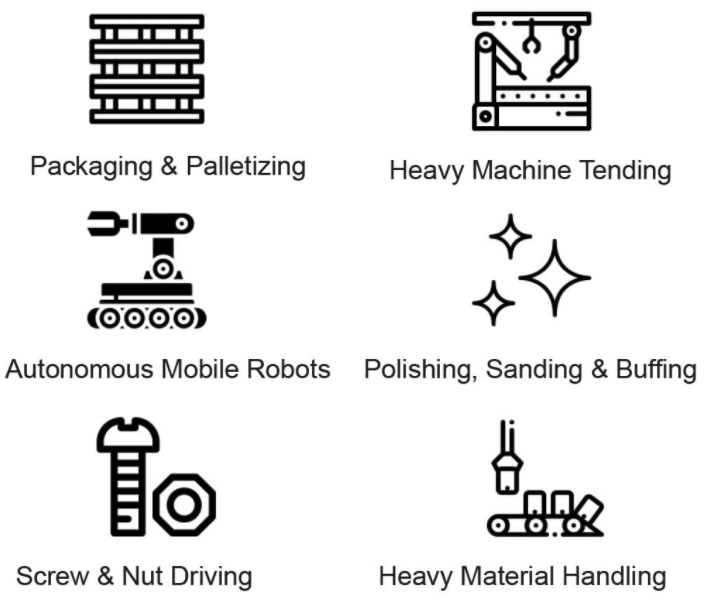

APPLICATIONS:

UR20: The UR20 is built for higher payloads, faster speeds, and superior motion control all within a lightweight, small footprint system for optimal versatility within your existing production space. No special electrical hookups or costly wiring solutions are required. Even with the big step up in performance, a single-phase standard power outlet is all that’s needed to power the UR20.

With a 1750 mm reach and 20 kg payload capacity, UR's next generation cobot handles more tasks, fits more applications, and assists in more environments than ever before.

Heavy payload, compact cobot

The UR30 can lift heavy payloads while maintaining a compact footprint in a collaborative setting. With a 30 kg lifting capacity and a 1300 mm reach this robot can tend larger machines, palletize heavy products, and effectively support high torque screw driving.

Building off the same architecture as the UR20, the UR30 offers extraordinary lift in a compact footprint with superior motion control ensuring the perfect placement of large payloads. With the ability to handle higher torque, the UR30 opens the door for precise screw driving and the 30 kg payload brings productivity to everything from machine tending with multiple grippers to palletizing heavy parts.

Autonomous Bin Picking for Machine Tending

The ActiNav Autonomous Motion Module (AMM) synchronously handles vision processing, collision-free motion planning, and autonomous real-time robot control.

ActiNav setup is intuitive using the Universal Robots teach pendant, teach by demonstration. The intuitive flow-based wizard-guided setup allows in-house resources to do the work in just six steps.

Higher machine uptime with collision-free motion: Autonomous collision-free motion within its environment means fewer operator interventions and system restarts.

Less refilling with deep bins: Autonomous motion enables ActiNav to operate inside deep bins which hold more parts, allowing the systems to run unattended longer and require less filling. When the bin gets low on parts, it notifies workers by an alert light that it’s ready for more parts.

Accurate part placement: Machine tending requires parts to be accurately placed and oriented in the same way each time. The high-resolution sensor and CAD matching enable high accuracy picks and ensures the part is placed in the same way into a fixture each time.

Fast, easy, low-risk integration

Fast, easy, low-risk integration

UR+ is the premier product platform to help you automate your applications more easily than ever before. Hundreds of industry-leading products are tested and approved to work with cobots from Universal Robots to provide you with fast deployment, simple programming and reliable operation. From grippers and accessories to vision systems and software – UR+ has a solution for you.

Copyright © 2022 · All Rights Reserved ·

Clayton Controls Inc. - Headquarters, 2865 Pullman Street, Santa Ana, CA 92705 Tel: 800-235-4411

Campbell Office, 1671 Dell Ave., Suite 110, Campbell, CA 95008 Tel: 800-341-4445

Central California Office, 109 Fox Street, Lemoore, CA 93245 Tel: 800-235-4411

Arizona/Southern Nevada Office, 4343 N. Scottsdale Road, Suite 150, Scottsdale, AZ 85252 Tel: 480-673-3327